Note: In common usage "neodymium" magnets refers to neodymium-iron-boron magnets (NdFeB). The terms are effectively interchangeable. This article uses "neodymium (NdFeB)" to describe that magnet class.

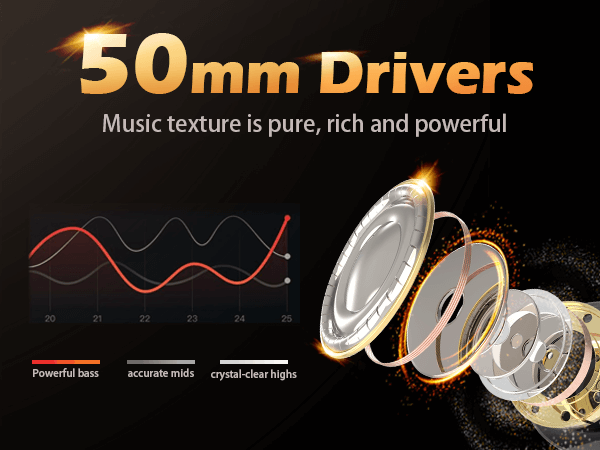

When evaluating headphone sound and performance, the driver’s magnet material plays a crucial role. Drivers convert electrical signals into sound, and the magnet type inside the driver affects sensitivity, transient response, bass control, and overall accuracy. Below we compare the most common magnet families used in headphone drivers and explain why neodymium (NdFeB) is widely favored for high-performance and professional headphones like the Talomen Ti660x and the Talomen W50x.

Common Driver Magnet Materials

Ferrite (Ceramic) Magnets

Ferrite magnets are inexpensive and commonly found in entry-level headphones. They are robust and stable but have lower magnetic energy compared with rare-earth magnets.

- Advantages: low cost, good corrosion resistance, stable over temperature

- Limitations: lower magnetic flux density → larger drivers or higher power needed for the same sensitivity

- Typical use: budget headphones and some portable speakers

Neodymium (NdFeB) Magnets

Neodymium magnets (NdFeB) are the most powerful commercially available permanent magnets. They combine neodymium, iron and boron (chemical formula often represented by the Nd2Fe14B phase) and deliver very high magnetic energy density.

- Advantages: highest magnetic flux per volume (very strong), allows smaller and lighter drivers with excellent sensitivity

- Audio benefits: tighter, more controlled bass; improved transient response; clearer mid/high detail; higher efficiency

- Practical notes: NdFeB magnets are often plated to prevent corrosion; they offer excellent performance for most headphone applications

Samarium-Cobalt (SmCo) Magnets

SmCo is another rare-earth magnet family. It is less common in consumer headphones due to higher cost, but it excels in temperature stability and corrosion resistance.

- Advantages: excellent thermal stability, good resistance to demagnetization, reliable in extreme conditions

- Limitations: more expensive and less commonly used in mass-market headphone drivers

- Typical use: specialized industrial or aerospace audio devices, some high-end niche audio applications

Quick Comparison

| Magnet Type | Key Strengths | Typical Trade-offs |

|---|---|---|

| Ferrite | Low cost, corrosion resistant, stable | Lower magnetic flux → larger drivers or lower sensitivity |

| Neodymium (NdFeB) | Highest energy density, compact drivers, high sensitivity and accuracy | More sensitive to corrosion (plating required); temperature stability lower than SmCo but fine for most headphone use |

| Samarium-Cobalt (SmCo) | Excellent thermal stability and demagnetization resistance | Higher cost; less common in consumer headphone drivers |

Why Neodymium (NdFeB) Is Preferred in High-Performance Headphones

Because NdFeB magnets provide very high magnetic flux in a small volume, driver designs using NdFeB can be more compact while still delivering:

- Higher sensitivity — easier to drive to loud volumes with less power

- Tighter, more controlled bass — the motor structure can produce stronger linear force on the diaphragm

- Improved transient response — faster diaphragm acceleration and deceleration for clearer detail

- Better efficiency — smaller drivers or lighter diaphragms can achieve the same output

Considerations & Practical Notes

While NdFeB is excellent for audio, there are a few practical considerations:

- Corrosion protection: NdFeB magnets are usually plated (nickel, zinc, or other coatings) because the raw alloy can corrode.

- Temperature: NdFeB has lower maximum operating temperature than SmCo; for consumer and studio headphone use this is typically not an issue, but designers account for it in material choice and assembly.

- Cost vs benefit: NdFeB is more expensive than ferrite but offers clear performance gains that justify the cost in mid-to-high-end and professional headphones.

What This Means for Listeners and Creators

For everyday listeners, headphones with neodymium (NdFeB) drivers deliver richer detail, tighter bass, and a more engaging soundstage at comfortable listening levels. For audio professionals—mixing engineers, producers and podcasters—NdFeB based drivers provide the accuracy and transient control required for critical monitoring.

Our Models

The Talomen Ti660x and Talomen W50x both use high-quality neodymium (NdFeB) drivers. These models combine large-diameter diaphragm design with rare-earth magnet motors to deliver a neutral, revealing response suitable for both studio monitoring and immersive listening.

Conclusion

In summary, when we say "neodymium" in the context of headphone magnets, we mean NdFeB — the powerful neodymium-iron-boron alloy that provides the best balance of size, sensitivity and sonic precision for modern headphones. While ferrite remains a cost-effective choice and SmCo offers specialized advantages, NdFeB is the go-to solution for most high-performance headphone designs.

Want to experience the difference? Explore our closed-back headphones collection and check the detailed specs for the Ti660x and W50x.

댓글 남기기

이 사이트는 hCaptcha에 의해 보호되며, hCaptcha의 개인 정보 보호 정책 과 서비스 약관 이 적용됩니다.